In the fast-paced world of Malaysia construction, BRC Mesh Malaysia has become a cornerstone material, renowned for its strength, versatility, and efficiency. This welded wire mesh, often used in reinforcing concrete, plays a pivotal role in modern construction projects across the country. From residential buildings to infrastructure such as bridges and roads, BRC Mesh is an integral component that ensures durability and integrity. This article explores the significance of BRC Mesh in Malaysia’s construction landscape, its benefits, and applications.

The Fundamentals of BRC Mesh

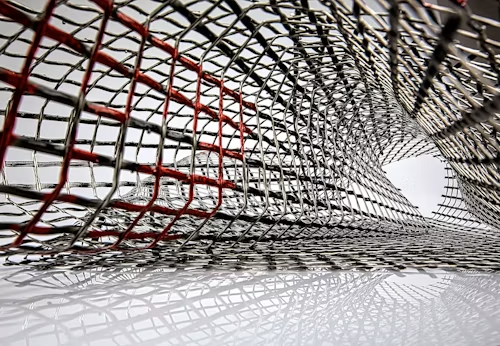

BRC Mesh, short for British Reinforcement Concrete, is a prefabricated steel reinforcement material made from welded wire fabric. It is characterized by its uniform spacing of wires and is widely used in concrete reinforcement to provide tensile strength and distribute loads evenly. In Malaysia, BRC Mesh is manufactured in accordance with local and international standards, ensuring its quality and suitability for various construction needs.

Key Benefits in Construction

The adoption of BRC Mesh in construction offers several significant benefits:

- Enhanced Structural Integrity: BRC Mesh reinforces concrete structures, helping them withstand tensile forces and preventing cracks and collapses.

- Cost Efficiency: Its prefabricated nature allows for quick and easy installation, reducing labor costs and construction time.

- Versatility: Available in various sizes and configurations, BRC Mesh can be used in a wide range of applications, from flat slabs and walls to cylindrical columns and beams.

- Durability: Made from high-quality steel, BRC Mesh is resistant to corrosion and environmental degradation, ensuring the longevity of the structures it reinforces.

Applications in Modern Construction

BRC Mesh is utilized in numerous construction projects across Malaysia, highlighting its versatility and effectiveness:

- Residential and Commercial Buildings: It is used in the floors, walls, and ceilings of buildings to enhance strength and stability.

- Infrastructure Projects: BRC Mesh is critical in the construction of highways, bridges, tunnels, and airports, providing the necessary reinforcement to endure heavy loads and environmental stress.

- Industrial Applications: Factories and warehouses benefit from BRC Mesh in their concrete floors and loading docks, accommodating heavy machinery and traffic.

- Environmental Structures: In erosion control, slope stabilization, and retaining walls, BRC Mesh helps maintain the integrity of landscapes and built environments.

Future Trends and Innovations

The future of BRC Mesh in Malaysia looks promising, with ongoing research and development focusing on enhancing its properties and applications. Innovations such as coated BRC Mesh for increased corrosion resistance and the integration of smart sensors to monitor structural health in real-time are on the horizon. These advancements will further cement BRC Mesh’s role in modern construction, addressing the evolving demands of the industry.

Conclusion

BRC Mesh is an indispensable component of Malaysia’s construction sector, offering unparalleled benefits in terms of structural integrity, cost efficiency, and versatility. As the industry continues to grow and evolve, the role of BRC Mesh in facilitating safe, sustainable, and efficient construction practices is undeniable. Understanding its significance and applications is crucial for professionals in the field, ensuring the continued development and resilience of Malaysia’s built environment.